Product Display

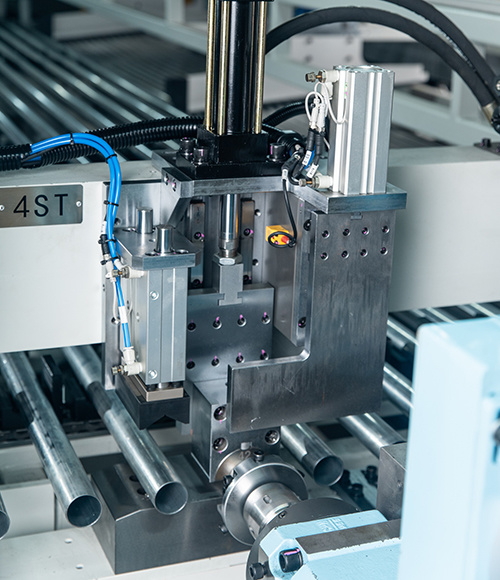

Fully automatic chamfer, test and print preduction line for welded tube

Product Catalog:

Finished product display

Tab ①

HTML language content can be parsed after rich text content is bound to data

Tab ②

HTML language content can be parsed after rich text content is bound to data

Tab ③

HTML language content can be parsed after rich text content is bound to data

Tab ④

HTML language content can be parsed after rich text content is bound to data

The information is a test element. When using, you can delete the element and place the element you want to put.

Feature Introduction

Advantage introduction

Details show

➢ The production line is docked with the pipe making machine, reducing manual handling during transfer.

➢ Chamfering, testing, and coding processes are automatically connected, achieving automatic transmission and reducing the workload of operators.

➢ Equipped with ATEQ high-precision leak detection instruments, realize the automatic air tightness test of the pipe, providing reliable quality assurance.

➢ The production line can automatically transfer, test and process without the involvement of operators, and improving production efficiency.

➢ The hydraulic system, pneumatic system, and electrical control system are installed on the upper platform of the equipment, reducing the footprint of the equipment.

➢ Cycle time: 80 seconds per pipe for Φ15-42mm; 180 seconds per pipe for Φ54-108mm.

Tab ④

HTML language content can be parsed after rich text content is bound to data

The information is a test element. When using, you can delete the element and place the element you want to put.